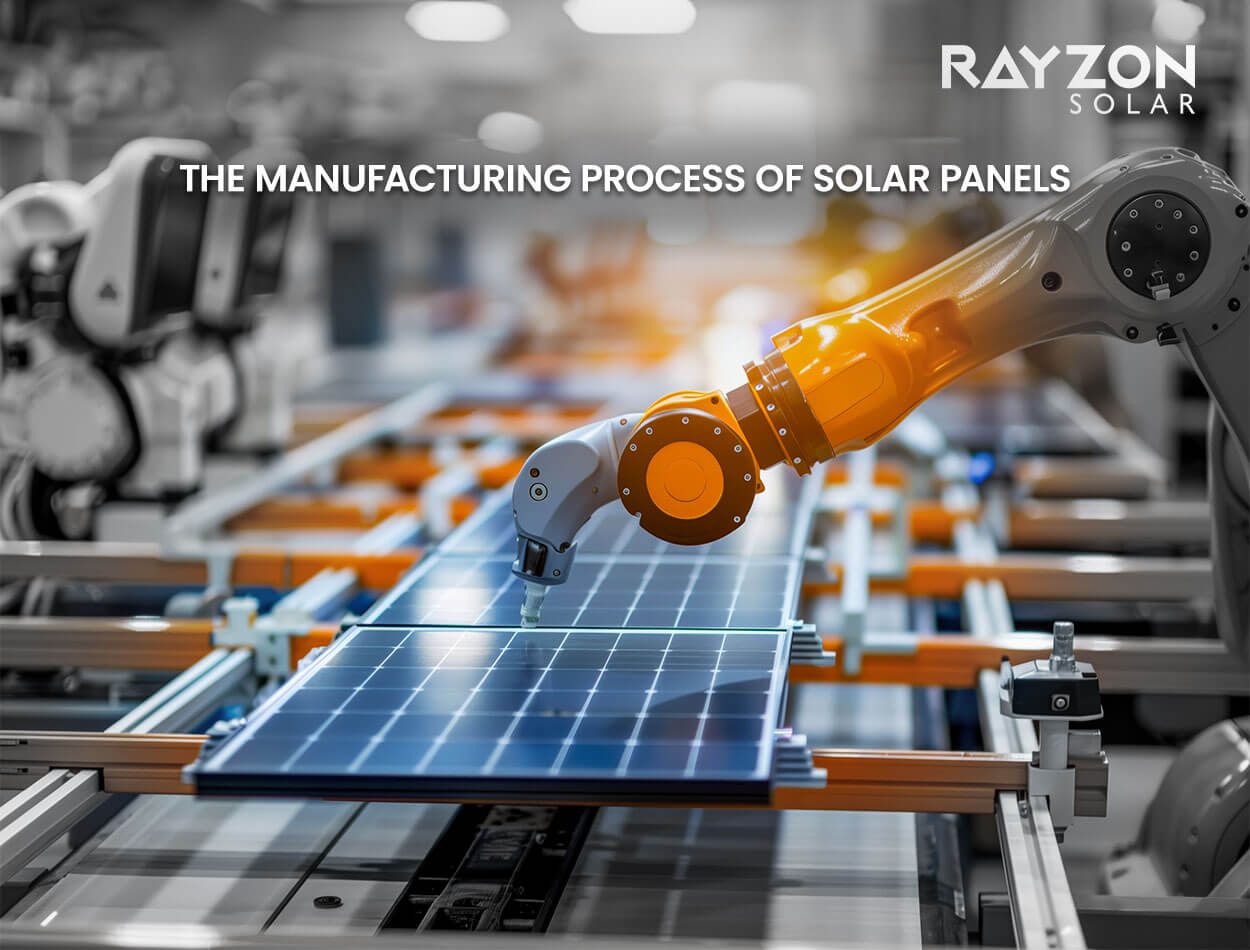

The Manufacturing Process of Solar Panels

Solar energy is rapidly becoming one of the most popular renewable energy sources worldwide. With the increasing demand for sustainable energy solutions, understanding the manufacturing process of solar panels is crucial. This blog will research the intricate details of how solar panels are made, focusing on various aspects such as Rayzon Solar the best solar panel manufacturer, the role of photovoltaic technology, and the overall impact on renewable energy in India. Rayzon Solar is leading the charge in producing the most efficient solar panels, contributing significantly to the renewable energy sector.

Understanding Solar Panels

What are Solar Panels?

Solar panels, also referred to as photovoltaic panels, utilize the photovoltaic effect to convert sunlight into electricity. This process involves the use of semiconductor materials that, when exposed to sunlight, generate an electrical current. Solar panels are important elements of solar power systems, serving a variety of applications such as residential solar panels, commercial solar panels, and solar rooftops.

Key Components

Solar Cells: The heart of a solar panel, made from silicon.

Encapsulation: Protects solar cells from moisture and mechanical damage.

Glass Cover: Shields the panel from environmental factors.

Frame: Provides structural support.

Junction Box: Helps electrical connections.

The Manufacturing Process of Solar Panels

Step 1: Silicon Purification

The primary material used in solar cells is silicon, resulting from quartz. Silicon purification involves heating quartz in a furnace to produce metallurgical-grade silicon. This silicon is then subjected to a chemical process called the Siemens process, which consists in reacting it with hydrochloric acid to produce trichlorosilane gas. The gas is then refined and reduced using hydrogen to produce highly pure electronic-grade silicon.

Step 2: Ingots Formation

Purified silicon is melted in a crucible at high temperatures. The molten silicon is then cooled and solidified into cylindrical or rectangular ingots. During this process, a seed crystal is introduced to guide the formation of a single crystal structure, ensuring that the silicon crystals align perfectly. This process, known as the Czochralski method, is essential for efficient electricity generation.

Step 3: Wafer Slicing

The silicon ingots are cut into thin wafers using wire saws covered with diamond particles. This cutting must be accurate to ensure uniform thickness and minimum waste. After cutting, the wafers are polished to remove saw marks and surface defects, making smooth, flat wafers ready for further processing.

Step 4: Doping

Wafers undergo a process called doping, in which specific layers such as phosphorus or boron are introduced to create a positive-negative (p-n) junction. This junction is essential for creating an electric field that enables the solar cell to convert sunlight into electricity. Doping is usually carried out using a diffusion furnace, where wafers are exposed to gaseous doping agents at high temperatures.

Step 5: Texturization

The wafers are textured to create a rough surface that reduces reflection and increases light absorption. This is achieved by etching the wafers in a chemical bath, usually containing potassium hydroxide (KOH), which creates a pyramid-like surface structure. This texturing helps to trap more sunlight, enhancing the efficiency of the solar cells.

Step 6: Anti-Reflective Coating

An anti-reflective coating is applied to the wafers to enhance their ability to absorb sunlight. This coating, usually made of silicon nitride, is applied using a process called plasma-enhanced chemical vapor deposition (PECVD). The coating minimizes the reflection of light, allowing more photons to enter the cell and generate electricity.

Step 7: Metal Contacts Application

Metal contacts are applied to the front and back of the wafers to facilitate the flow of electricity. The front contacts are typically fine grid lines made of silver, which collect electrons generated by the cell. The back contact, usually made of aluminium, forms a continuous layer that helps to reflect any unabsorbed light into the cell. These contacts are applied using screen printing and then fired in a furnace to form a good electrical connection.

Step 8: Solar Cell Formation

The treated and coated wafers are now individual solar cells. These cells are tested for efficiency and electrical output to ensure they meet the required performance standards. Cells that do not meet the standards are rejected or reprocessed.

Step 9: Stringing

Solar cells are interconnected using thin metal ribbons to form a string. This is done using an automatic stringing machine, which aligns and solders the cells together. Multiple strings are then connected to create a solar panel module. The number of cells in a string and the configuration depend on the desired voltage and current output of the panel.

Step 10: Encapsulation

The interconnected cells are sandwiched between layers of ethylene-vinyl acetate (EVA) for protection against moisture and mechanical damage. EVA sheets are placed on both sides of the cell string. This encapsulation process helps to cushion the cells and provides thermal and UV stability.

Step 11: Laminating

The encapsulated cells are placed between a tempered glass cover and a protective back sheet. This laminate is then heated in a laminator to cure the EVA, bonding the layers together into a single, durable unit. The tempered glass protects the cells from environmental factors while allowing sunlight to pass through.

Step 12: Framing

The laminated panel is fitted with an aluminium frame, providing structural support and making it easier to mount. The frame also helps protect the panel's edges from impact and moisture ingress. It includes mounting holes and grounding points to facilitate installation.

Step 13: Junction Box Attachment

A junction box is attached to the back of the solar panel to house the electrical connections and protect them from the environment. The junction box contains bypass diodes to protect the panel from shading and ensure efficient energy output. It also provides a secure point for connecting the panel to the external electrical system.

Step 14: Sealing

The edges of the panel are sealed with silicone to prevent moisture ingress, which can damage the cells and reduce efficiency. This sealing process is critical for ensuring the long-term durability and performance of the panel, particularly in tough environmental conditions.

Step 15: Electrical Testing

Each solar panel needs hard electrical testing to ensure it meets efficiency and durability standards. This includes performance tests under simulated sunlight conditions (flash testing) to measure the panel’s power output, voltage, current, and efficiency. Panels that pass these tests are labelled with their electrical ratings.

Step 16: Visual Inspection

Panels are visually inspected for defects, such as cracks or chips in the glass, irregularities in the encapsulation, and alignment issues. This step ensures that only panels with a perfect appearance and structure reach the market.

Step 17: Certification

Solar panels must pass industry-standard certifications, such as IEC (International Electro Technical Commission) standards, to ensure quality and safety. Certification tests include environmental testing (temperature, humidity, UV exposure), mechanical load tests, and electrical safety tests. These certifications are crucial for gaining market acceptance and ensuring reliable performance.

Step 18: Packaging and Shipping

The finished panels are carefully packaged to prevent damage during transport and are then shipped to distributors and installers worldwide. Packaging typically includes protective padding and weather-resistant materials to ensure the panels arrive in perfect condition.

Benefits of Solar Panels

1. Renewable Energy Sources

Solar panels harness the power of the sun, a renewable resource, to generate electricity. This reduces dependence on fossil fuels and helps mitigate climate change.

2. Cost Savings

Investing in solar panels can lead to significant cost savings on electricity bills. Solar subsidies and schemes like PM Surya Ghar Yojana further reduce the upfront costs, making solar energy more accessible.

3. Environmental Impact

Solar energy is a clean, green energy source that reduces carbon footprints and air pollution. The adoption of solar power systems contributes to a healthier planet.

Read More :Benefits of Solar Energy

Solar Panel Installation and Maintenance

Installation Process

The installation of solar panels involves several steps:

- Site Assessment: Evaluating the location for optimal sunlight exposure.

- Design and Permitting: Customizing the solar system design and obtaining necessary permits.

- Installation: Mounting the panels on rooftops or ground-mounted structures.

- Connection: Linking the panels to the inverter and electrical grid.

Read More: The Process of Installing Solar Panels

Maintenance Tips

Proper maintenance ensures the longevity and efficiency of solar panels:

- Regular Cleaning: Removing dust and debris to maintain optimal efficiency.

- Inspection: Periodic checks for any damage or wear.

- Monitoring: Using monitoring systems to track performance.

Read More: Solar Panel Maintenance Guide

Conclusion

The manufacturing process of solar panels is a complex yet fascinating journey from raw silicon to a fully functional solar power system. Leading company Rayzon Solar is at the forefront of this industry, producing some of the best solar panels available. With the continued advancements in solar technology and strong governmental support, the future of renewable energy in India looks bright. Investing in solar panels not only offers financial benefits but also contributes to a sustainable and eco-friendly future.

By comprehending the complexities of solar panel production and its advantages, we can make informed choices to support the expansion of renewable energy sources and ultimately contribute to a more sustainable planet.

You Can Also Read This: Top 3 Things to Look for in Solar Panels