The Role of Automation in Modern Solar Panel Production

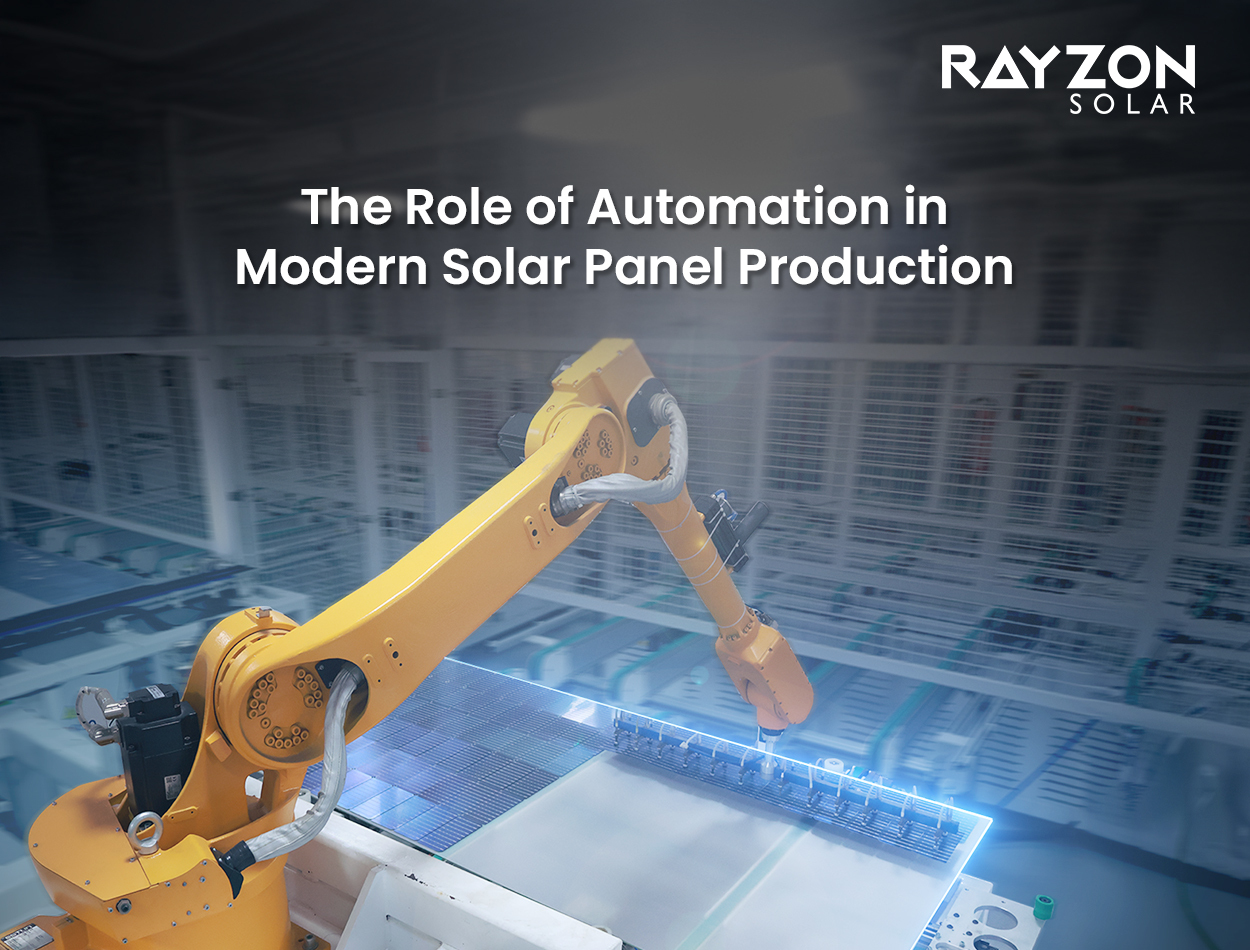

In the rapidly evolving solar energy sector, automation in solar panel production is emerging as a cornerstone of modern manufacturing processes. By integrating advanced technologies like AI, robotics, and IoT, companies such as Rayzon Solar are redefining how solar panels are designed, assembled, and distributed. This transformation not only enhances efficiency but also aligns with the global push for sustainable energy solutions.

With demand for renewable energy surging, the need for modern solar panel manufacturing practices has never been greater. Automated processes are addressing challenges like labour shortages, cost efficiency, and product consistency, making solar panels more accessible and reliable than ever.

The Impact of Automation on the Solar Power Industry

In the solar power industry, automation has made significant inroads, bringing about transformative changes in production efficiency, maintenance, safety, and energy distribution.

Enhancing Production Efficiency

Automation has played a crucial role in enhancing production efficiency in the solar power industry. Automated manufacturing processes, for instance, have reduced the time and resources spent on assembling solar panels, improving overall productivity.

Moreover, automation has led to increased precision in the manufacturing process, reducing errors and waste. This, in turn, has resulted in higher-quality solar panels that deliver better performance and longer lifespan.

Here is a table illustrating the impact of automation on production efficiency:

| Factor | Before Automation | After Automation |

| Production Time | High | Reduced |

| Resource Utilization | High | Optimized |

| Error Rate | High | Reduced |

| Product Quality | Variable | Improved |

Improving Maintenance and Safety

Automation has also improved maintenance and safety in the solar power industry. One key area is the use of drones for routine inspections of solar panels. This not only makes the inspection process quicker and more efficient but also reduces the risk of accidents and injuries.

Furthermore, automation technologies enable predictive maintenance, identifying potential issues before they become major problems. This proactive approach reduces downtime and extends the service life of solar power installations.

Streamlining Energy Distribution

Automation also plays a vital role in streamlining energy distribution in the solar power industry. Advanced algorithms and control systems can automatically adjust the flow of electricity based on demand, improving the efficiency and reliability of power distribution.

Moreover, smart grids, which leverage automation and AI, can manage energy distribution more dynamically and flexibly. They can respond in real-time to changes in energy supply and demand, optimizing the use of solar power and ensuring minimal wastage.

Learn more about the transformative impact of smart grids in our article on energy optimization in solar manufacturing: The Manufacturing Process of Solar Panels.

What Is Automation in Solar Panel Production?

Automation in solar panel production involves leveraging technologies such as robotics, machine learning, and smart sensors to optimize the entire manufacturing process. From silicon wafer slicing to module assembly, these technologies minimize human intervention while maximizing accuracy and speed.

Key components of automated solar manufacturing include:

- Robotics in Solar Manufacturing: Robotic arms handle delicate tasks like stringing solar cells, improving precision and reducing waste.

- AI-Driven Optimization: Machine learning algorithms predict maintenance needs and optimize production schedules for uninterrupted operations.

- IoT in Smart Solar Factories: Connected devices monitor equipment performance and energy consumption in real time.

Benefits of Automated Solar Panel Production

- Increased Efficiency: Automation significantly reduces production time, allowing manufacturers like Rayzon Solar to meet growing global demand swiftly.

- Cost Reduction: Automated processes minimize labour costs, wastage, and energy consumption, leading to more cost-effective solutions.

- Enhanced Quality Control: Precision robotics and AI-driven monitoring ensure consistent product quality.

- Scalability: Automated production lines are designed to efficiently expand operations, enabling seamless handling of high-capacity demands.

- Improved Sustainability: Automated factories are designed to optimize energy use, contributing to a lower carbon footprint.

- Workforce Reallocation: Automation allows human workers to focus on higher-value tasks like R&D and system management, boosting innovation.

The Impact of Robotics and AI in Solar Manufacturing

1. Robotic Assembly in Solar Panel Production:

Robotic systems handle intricate processes such as cell placement and soldering, ensuring uniformity and reducing errors. These systems are crucial in modern solar factories, where high throughput is essential.

2. AI in Solar Panel Production:

AI algorithms analyze vast amounts of data to identify inefficiencies, predict potential equipment failures, and suggest process improvements. For instance, AI can optimize energy consumption in smart solar factories.

3. IoT Integration:

IoT-enabled devices in production lines provide real-time insights into machine performance and energy consumption, helping reduce downtime and operational costs.

4. Case Study: Rayzon Solar’s Modern Manufacturing Facilities

Located in Gujarat, Rayzon Solar’s 4GW production capacity is powered by automated technologies that enhance efficiency and maintain the highest standards of quality. Learn about our process.

Challenges in Automating Solar Panel Production

Despite its advantages, automation in solar manufacturing faces several challenges:

- High Initial Investment: Setting up automated production lines requires substantial capital.

- Technical Complexity: Integrating AI, robotics, and IoT demands specialized expertise.

- Adaptation to Rapid Technological Changes: Manufacturers must continuously upgrade their systems to stay competitive.

Solutions:

- Partnering with technology providers for seamless integration.

- Investing in workforce training programs to manage and maintain advanced systems.

- Leveraging government incentives for adopting green manufacturing technologies. Explore Solar Incentives.

Future Trends in Automated Solar Manufacturing

The solar manufacturing industry is on the brink of significant advancements, with trends such as:

- AI-Powered Predictive Maintenance: Ensuring minimal downtime by predicting potential failures before they occur.

- Green Manufacturing Processes: Adoption of renewable energy sources within factories to further reduce carbon footprints.

- Digital Twins: Simulating production processes digitally to test and optimize workflows without disrupting operations.

- Collaborative Robotics (Cobots): Cobots work alongside humans to increase flexibility and efficiency in manufacturing.

FAQs on Automation in Solar Panel Production

- How does automation improve solar panel production efficiency?

Automation reduces production time, minimizes errors, and optimizes resource utilization, ensuring faster and more efficient manufacturing.

- What technologies are used in automated solar manufacturing?

Technologies include robotics, AI, IoT, and machine learning to enhance precision, monitoring, and scalability.

- What are the main challenges in adopting automation in solar production?

Challenges include high initial costs, technical complexities, and the need for specialized expertise.

- How does automation impact the cost of solar panels?

Automation reduces labour costs, wastage, and operational inefficiencies, making solar panels more affordable for consumers.

- Why is Rayzon Solar a leader in automated solar production?

Rayzon Solar combines advanced robotics, AI, and IoT with a commitment to quality, innovation, and sustainability, ensuring top-tier solar solutions. Discover Our Milestones.