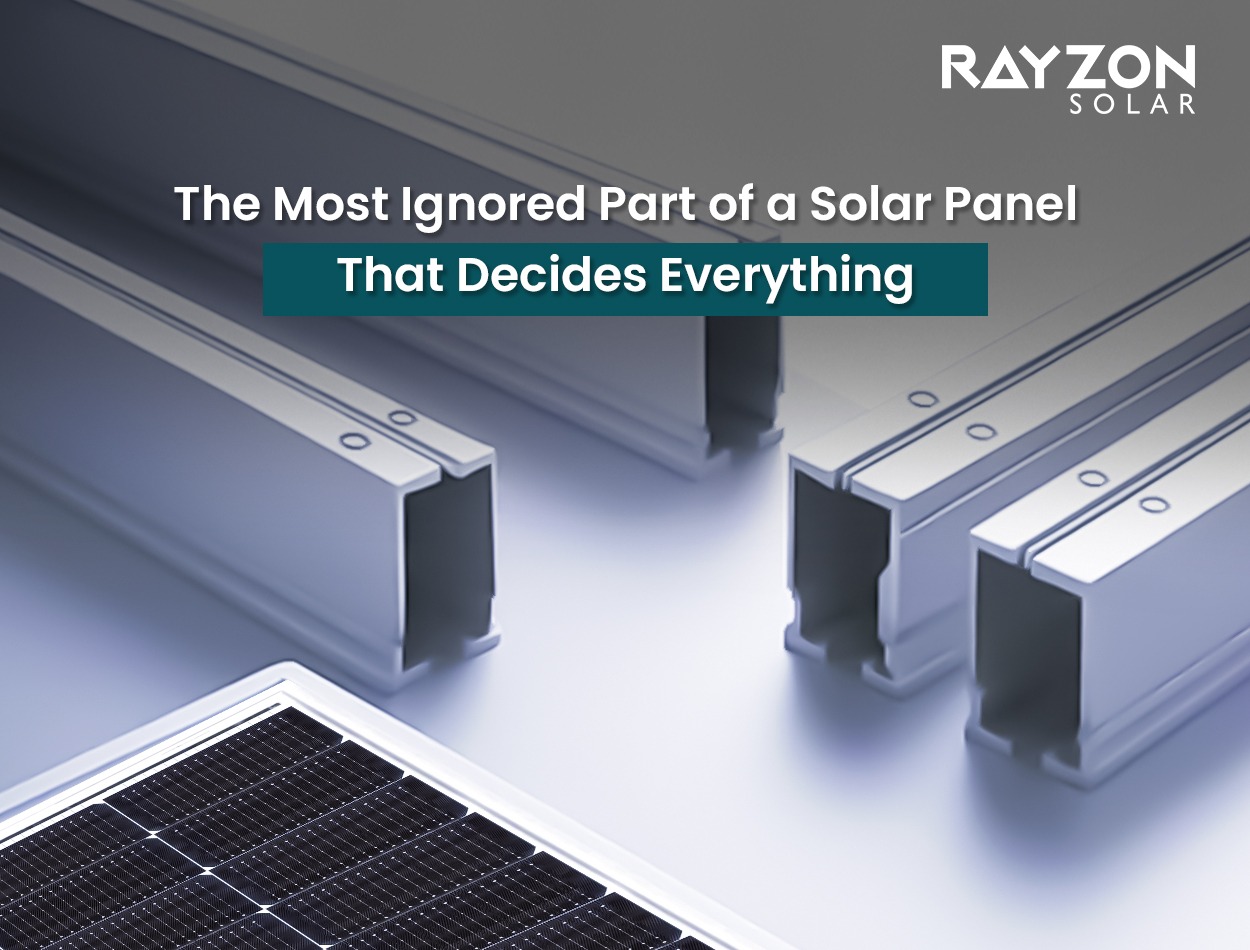

The Most Ignored Part of a Solar Panel That Decides Everything

In the solar industry, innovation conversations revolve around core technology, i.e. wafers, cells and efficiency upgrades or alternate technologies evolving with them. Yet one component—quiet, structural, and rarely discussed—plays a defining role in keeping all the components and layers of modules together, safe from external harsh weather for a long life of Solar module is Aluminium frames.

As climate change and severe weather conditions are norms of everyday life, over and above individual solar components, we must choose a frame that maintains its quality and strength for the life of solar modules.

At the onset, we can’t treat Aluminium frames as a passive component anymore. They are effectively the mechanical backbone of a solar module. While there is always a cost pressure on optimisation of overall solar module cost, careful consideration needs to be given towards design, choice of material, as well as quality of manufacturing of Aluminium frames, and the industry is aware of the same and is taking steps cautiously while designing frames.

Why Aluminium Frames Matter More Than You Think

Solar modules installed today endure far more complex environmental pressures than even a decade ago—coastal corrosion, extreme temperatures, heavy wind loads, high humidity, and rainfall intensity. The frame’s job is to protect the module against all of these external harsh conditions.

A high-quality aluminium frame:

- Prevents glass breakages

- Reduces micro-cracks

- Maintains lamination stability

- Resists corrosion

- Holds structural integrity during adverse weather conditions and

- Minimises long-term degradation

Modules are judged by their efficiency. But they survive mechanically because of their frames.

How Frame Quality Impacts Real-World Generation

The industry tends to view generation loss only through the lens of cell degradation or environmental soiling. But structural degradation is just as influential—and far more preventable.

1. Micro-Cracks from Glass Flexing

Even minor flexing under wind stress can induce micro-cracks in the cells, slowly killing the output of the module and in long term reliability of module itself. A strong frame significantly reduces this risk.

2. Thermal Expansion Stress

In India, we see huge swings in temperature within the day as well as across the year. These temperature swings expand and contract the frames as a mechanical property throughout the day; the onset quality of the frames makes them absorb these thermal shocks or break them under stress.

3. Corrosion Creates Hidden Failures

Low-quality as well as thin layer of anodising can lead to corrosion—especially in humid, coastal, or polluted areas—compromising mechanical strength long before the module’s warranty ends.

4. Tracker & Rooftop Fatigue

Tracker systems and high-rise rooftops expose modules to repeated vibrations and uplift forces. Only frames with the right alloy strength and extrusion precision survive long-term cyclic stress.

This is why durability starts from the outside, over and above inside.

The Engineering Inside a Reliable Aluminium Frame

What truly differentiates frames is their design and engineering, and not only appearance.

The Alloy & Temper

The standard 6063-T6 alloy works well when purity, heat treatment, and temper accuracy are carefully controlled. Imprecision here means reduced longevity under mechanical load cycles.

Extrusion Precision

A good extrusion delivers:

- Accurate corner fits

- Uniform wall thickness

- Perfect linearity

- Even load distribution

A variation of even 0.1 mm can affect module sealing, clamp grip, and overall stability.

High-Quality Anodising

This is the first layer of defense against corrosion. A strong anodised layer is:

- Uniform

- Deep

- Smooth

- Chemically stable

Many frames in the market compromise on anodising thickness to save cost, leading to early corrosion and reduced torque retention.

An aluminium frame is a structural engineering product, not a commodity; it needs to be treated accordingly.

Why Global Markets Prioritise Strong Frames

Developed solar markets treat frames as critical components because they’ve learned from real-world disasters.

- Japan: Typhoons pushed the industry to develop high-load, high-torque-resistant frames.

- U.S. Hurricane States: Frames must withstand extreme uplift forces and high-speed debris impacts.

- Europe: Heavy snow loads demand superior mechanical stability.

India is entering this phase now. As installations expand across diverse terrains—deserts, coasts, industrial zones, and high-rise buildings—the expectation from frames is rising rapidly.

What the Future of Aluminium Frames Looks Like

As solar manufacturing matures, the industry will see the emergence of:

- Lighter yet stronger extrusion designs

- AI-based load simulations for frame engineering

- Aluminium circularity with higher-grade recycling

- Low-chemical anodising for sustainability

- Specialized frame structures for floating and hybrid systems

Future panels will generate more power—but the ones that last longer will be built on better frames.

Rayzon Solar: Raising the Bar for Aluminium Frame Quality in India

With India pushing toward deeper manufacturing integration, Rayzon Solar has taken a decisive step forward by establishing its own advanced aluminium extrusion and anodising facility.

Rayzon’s frame manufacturing aligns with global mechanical-load expectations and focuses on lifecycle reliability. The facility is designed with:

- High-purity aluminium billets for superior alloy consistency

- Precision-controlled extrusion lines for exact dimensions and structural stability

- Advanced anodising with strict control over layer thickness and uniformity

- Rigorous strength, corrosion, and torque testing aligned with international standards

- Frames engineered for tracker, rooftop, desert, and coastal environments

By internalising frame manufacturing, Rayzon eliminates dependency on variable-quality outsourced frames and ensures that every module carries a structurally robust backbone.

This move reflects a simple but powerful belief:

A solar module’s performance is not defined by its efficiency alone—but by the strength that protects that efficiency and performance for decades.

Rayzon’s aluminium anodising plant is setting a new benchmark in frame quality for the Indian solar industry—making long-lasting solar possible, scalable, and dependable.